Basic activated sludge process consists of the following 3 basic components

-

A reactor in which the microorganism responsible for treatment are kept in suspension and aerated

-

Liquid-solids separation in a sedimentation tank

-

A recycle system for returning solids removed from the liquid-solids separation unit back to the reactor (to maintain a sufficient conc. of biomass in the aeration tank)

Types of activated-sludge process

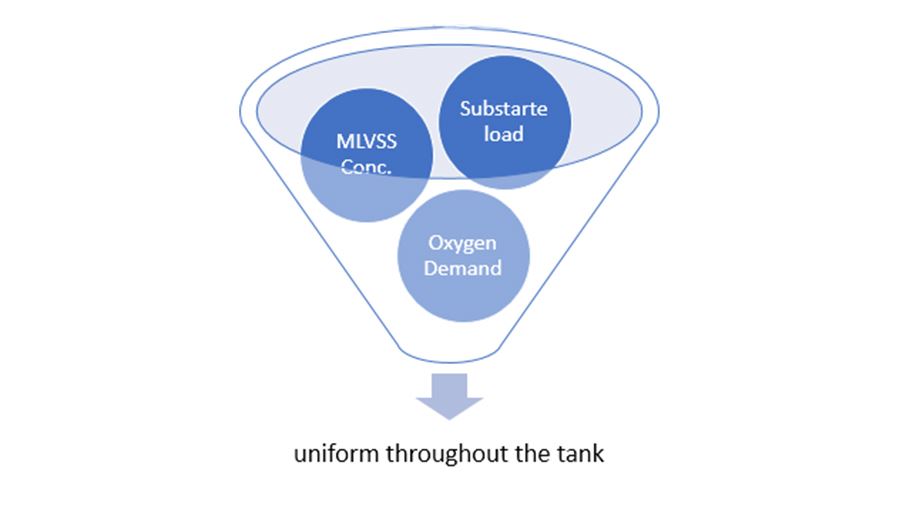

1. Complete mix reactors

-

Tank contents are thoroughly mixed

-

Substrate conc. in the effluent is same as the substrate conc. in the reactor

-

Relatively simple to operate but to have low organic subs. conc. (i.e low F/M) that encourage the growth of filamentous bacteria causing sludge bulking

-

Care should be taken to prevent short-circuiting of untreated or partially treated ww (influent and effluent withdrawal points selection are important)

-

If shock loads or toxic discharges (large number of industrial connections) are a design consideration a complete mix reactor can more easily withstand changing ww characteristics because the incoming ww is more or less uniformly dispersed with the reactor contents

-

Complete mix reactors are superior to plug flow reactors where wide fluctuations in flow rates occur 5

-

However, in actual practice, a true plug flow regime is essentially impossible to obtain because of longitudinal dispersion caused by aeration & mixing by dividing the aeration tank into a series reactors (staged reactor design) process approaches plug flow kinetics with improved treatment efficiency compared to a complete mix process

2. Plug flow reactors

This process involves relatively long, narrow aeration basins, so that the concentration of soluble substances and colloidal and suspended solids varies along the reactor length. All particles entering the reactor stay in the reactor for an equal amount of time. Substrate conc. is continuously varying of distance in the reactor at the influent end there is high readily degradable substrate & at the effluent end there is low readily degradable substrate where loading is reasonable constant, plug flow systems produce a more mature sludge with excellent settling characteristics. The true plug flow system is theoretically more efficient in the stabilization of most soluble wastes than in continuous flow stirred tank reactors. In actual practice, a true plug flow regime is essentially impossible to obtain because of longitudinal dispersion caused by aeration & mixing

-

80-90% removal of bacteria & 90‐99% removal of viruses.

-

Uninterrupted power supply required for aeration and sludge recirculation.

-

Proven and tested methodology all over the world for the last 7‐8 decades.

-

Several modifications available for specific requirements.

-

Reactor sludge levels to be carefully monitored and sludge is to be withdrawn from the system.

3. Additional Processes

This process involves relatively long, narrow aeration basins, so that the concentration of soluble substances and colloidal and suspended solids varies along the reactor length. All particles entering the reactor stay in the reactor for an equal amount of time. Substrate conc. is continuously varying of distance in the reactor at the influent end there is high readily degradable substrate & at the effluent end there is low readily degradable substrate where loading is reasonable constant, plug flow systems produce a more mature sludge with excellent settling characteristics. The true plug flow system is theoretically more efficient in the stabilization of most soluble wastes than in continuous flow stirred tank reactors. In actual practice, a true plug flow regime is essentially impossible to obtain because of longitudinal dispersion caused by aeration & mixing

-

Preliminary Treatment

-

Screening

-

Grit Removal

-

Tertiary Treatment – Filters

-

Solids Handling .

-

Recycle Flows.

Web Mail : Info@atkinsindia.com

Web Mail : Info@atkinsindia.com Customer Care Number : +91 9992227788

Customer Care Number : +91 9992227788 Web Link : www.atkinsindia.com

Web Link : www.atkinsindia.com