DAF- Dissolved Air flotation in Wastewater

DAF is a water & wastewater treatment system which remove contaminants like oil and suspended solids. In DAF system wastewater is treated by dissolving air in wastewater under pressure and then released at atmospheric pressure in a flotation tank basin. It is one of the most effective and versatile process in water treatment. Depending upon the type of filtration system DAF can be installed after pre-treatment or at initial. In some industries like oil & flammable gases, DAF unit use nitrogen as medium because as compared to air, nitrogen has less risk of explosion.

Process Design of DAF System

-

Fine Screening- It is the removal of the heavy matter prior to flotation pretreatment process. It basically reduced load of basically non—floating, heavy solids going towards DAF. It is important to remove these heavy matters so they don’t block pumps and piping.

-

Equalization- It provides a constant & less variable load to the DAF system which improves the efficiency and quality of effluent. A sufficient amount if mixing is required to retention time to keep solids to settle and oil grease from collecting from the surface.

-

pH Control – Most flocculation’s and coagulation optimize pH range. Apart from this most wastewater treatment system requires a separate pH control system to maintain pH.

-

Flocculation Control – In many wastewater treatment system a unit is provided for addition of flocculants and coagulants to achieve the effective flocculation of contaminants prior to flotation.

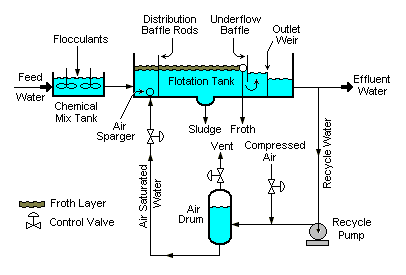

Flow Diagram of DAF Unit

Process of DAF- Dissolved Air Flotation

Feed water is added to the DAF float tank or chemical mix tank in which small particles are formed into big particles by adding coagulant like ferric chloride and aluminum sulphate which coagulate the smaller particle to form cluster. Then the effluent water is pumped to the small vessel in which air pressure is maintained with the help of air compressor which helps in saturation of pressurized water with air. Waste water is recycled through recycling pumps passing through air compressor to air drum & then into float tank again.

Why DAF is used ?

-

Recovery & reuse of waste water

-

To meet desired parameters before discharging water.

-

Thickening of Biosolids

-

For better effluent quality & reduce load on ongoing biological treatment system

-

High removal efficiency & easy sludge thickening or removal

Features of Atkins Enviro DAF Unit

Atkins Enviro Water Technologies is a water & wastewater treatment company that is manufacturing & supplying water & wastewater treatment from last two decades. With continue R&D & multiple installation we have made a fully developed DAF system for a variety of application. Atkins Enviro DAF unit provides unique features: -

-

Customized models available according size and type of application.

-

Prefabricated SS 304 Skid for long life and easy installation.

-

Circular or rectangular profile to utilize maximum space.

-

Extended retention time give better effluent quality.

-

Designed for low velocity to achieve better separation

-

Maximum & easy removal of sludge by thickening it.

-

Corrosion resistance

-

High temp & wide pH tolerance

Key Components of DAF System

-

Skimmer System

-

flotation Cell

-

Contact Chamber

-

Influent

-

Air Saturation System

-

Bottom Skimmer System

-

Float

-

Effluent Discharge Chamber

Web Mail : Info@atkinsindia.com

Web Mail : Info@atkinsindia.com Customer Care Number : +91 9992227788

Customer Care Number : +91 9992227788 Web Link : www.atkinsindia.com

Web Link : www.atkinsindia.com