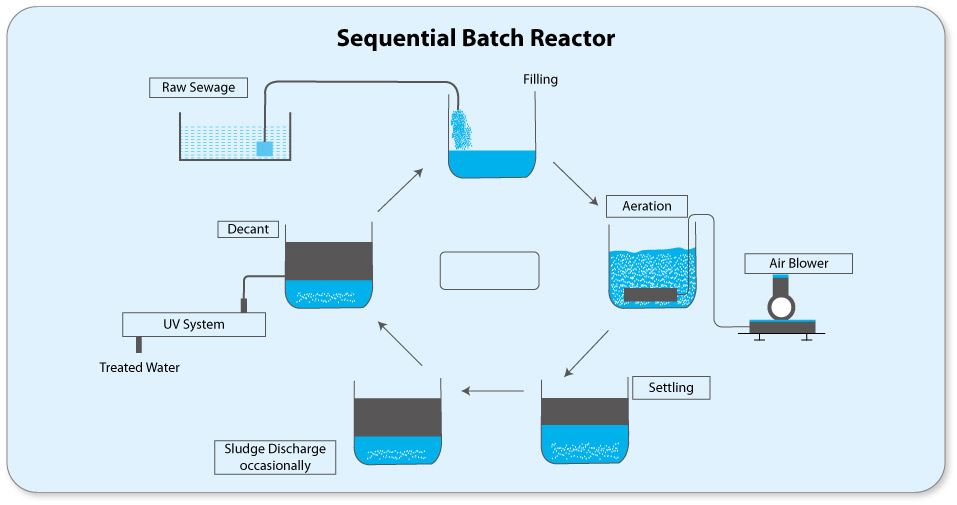

SBR- Sequencing Batch Reactors

This is a variant of Activated Sludge Process (ASP) technology & is essentially a batch treatment by combination of primary settling, aeration, secondary settling and decanting the treated sewage in a series of sequenced and or simultaneous reactions in the same basin on a time deferred cycle. Thus, among the multiple basins, one basin is used in one part of the cycle of aeration, settling and discharging the treated sewage in a cyclically repeated operation is done in another tank. Membrane of high efficiency fine bubble non-clog for diffused aeration is preferred.

Schematic flow diagram of Sequencing Batch Reactors process is presented

The essential components of SBR’s are:

-

Reactor basin

-

Waste sludge draw-off mechanism

-

Aeration equipment

-

Effluent decanter

-

Process control system

Advantages

-

The stabilized sludge is generated

-

Absence of odour and corrosive gases & can remove N and P concurrent with BOD.

-

Less manpower is required due to automatic control, easy operation & maintenance.

-

High quality effluent for reuse without separate nutrient removal and fine filtration.

-

Can be expanded as a modular system.

-

Capability to manage and treat variable loading conditions such as normal, dilute monsoon, diurnal and shock loads.

-

Can also be used with primary clarifiers and conventional F/M ratio for bio-methanation and energy recovery.

-

Separate secondary clarifiers and major return sludge pumping stations are not required, good use of common walls, simple square, rectangular or circular structures, can reduce the footprint compared to 5 conventional activated sludge process.

Disadvantages

-

At least semi-skilled manpower is required.

-

Patented process technology and decanters defying local cannibalization

-

No provision for sludge management

-

No provision of primary treatment to moderate pollution load variations.

-

Higher energy input if used without bio-methanation

Web Mail : Info@atkinsindia.com

Web Mail : Info@atkinsindia.com Customer Care Number : +91 9992227788

Customer Care Number : +91 9992227788 Web Link : www.atkinsindia.com

Web Link : www.atkinsindia.com