Up flow Anaerobic Sludge Blanket Process

Anaerobic treatment is widely used around the world as a biological stage in both domestic and industrial wastewater-treatment plants. The two main advantages of Atkins Enviro’s anaerobic treatment are the production of biogas, which can be used as fuel, and the lower rate of biomass production as sludge produced is only 5-10% also reducing cost of sludge disposal, which results in lower maintenance costs for the plan. Also this system uses biology, thus without using air or oxygen the anaerobic microorganisms convert organic pollutants into a “biogas” which contains methane and carbon dioxide.

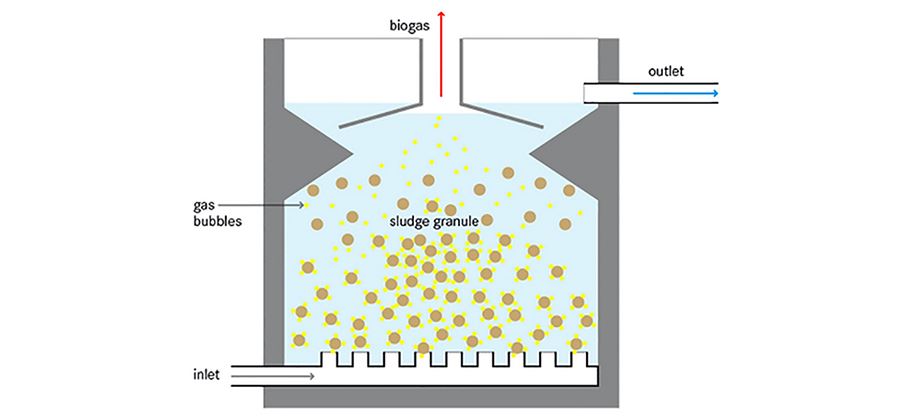

The above diagram shows the simplified version of Atkins Enviro’s UASB.

The sludge blanket is comprised of microbial granules (1 to 3 mm in diameter). The microorganisms in the sludge layer degrade organic compounds. Because of the up flow regime, granule-forming organisms are preferentially accumulated as the others are washed out.

After several weeks of use, larger granules of sludge form which, in turn, act as filters for smaller particles as the effluent rises through the cushion of sludge. Coming in contact with the granules the treatment occurs.

The gas thus released is methane and carbon dioxide, and this needs no mechanical assistance. The sloped walls of Atkins Enviro’s USAB deflects the rising material downwards, and only the clarified or treated effluent goes out via outlet at the top.

The important design features of Atkins Enviro’s system are

Among the main applications for Atkins Enviro’s UASB are in the beverage, brewery, food and tannery industries.

| S.No | Parameters | Particulars |

|---|---|---|

| 1 | Solid retention time | 40 days |

| 2 | Temperature of reactor | 20º - 32º C |

| 3 | BOD removal yield coefficient | 0.1 g VSS /g |

| 4 | COD removal efficiency | 80% |

| 5 | Average concentration of sludge in blanket | 75% |

This simple and efficient system of Atkins Enviro India has many advantages along with the guarantee of prompt maintenance service and highly economical installation and operations, they are:

-

Atkins Enviro’s system can withstand high organic loading rates (up to 10kg BOD/m3/d) and high hydraulic loading rates.

-

Process not vulnerable to power cuts.

-

Recovery of gas with high calorific value.

-

The COD removal efficiency is 70-80 % and the specific gas production is 0.577 m3kg-1 of COD removed per day.

-

Low sludge production

-

No primary treatment, suspended solids in the waste water acts as carrier material for microbial attachment.

-

Post treatment of UASB is invariably required.

-

Needless to mention the guarantee of Atkins Enviro’s quality, in terms of product, maintenance, & operational economy.

Atkins Enviro’s SAFF Technology, is not only simple in design (with no moving parts in operation are) but they are economical too; moving parts are stationed in such a way so as to facilitate quick maintenance. SAFF technology is designed to reduce organic loading, thus reducing the BOD (Biological oxygen demand) and impressive reduction of suspended particles, if untreated will contaminate the environment.

Web Mail : Info@atkinsindia.com

Web Mail : Info@atkinsindia.com Customer Care Number : +91 9992227788

Customer Care Number : +91 9992227788 Web Link : www.atkinsindia.com

Web Link : www.atkinsindia.com